Jobs & Career

Support & Training

News blog

Contact

QUNDIS Portal

Reporting office & complaints procedure

FAQ

Below you will find an overview with answers to frequently asked questions. If you cannot find the information you are looking for on this page, please call us on +49 361 26 280-0 or send an e-mail to info@qundis.com.

In our devices we normally have the clock set to winter time. This means that the set starting time is correct in winter, but one hour too late in summer. For this reason, the starting time is set one hour earlier for the whole year. To compensate, the device transmits one hour longer in summer with the stopping time set for winter. We ensure the starting and stopping times expected by the meter reader throughout the year by starting transmission one hour earlier in winter and continuing one hour longer in the evening in summer.

In addition, one hour each is added to the starting and stopping times in order to allow for clock accuracy. This ensures that in 10 years' time the device clock will not deviate by more than one hour from the actual time. By adding this tolerance to the starting and stopping times, it is ensured that even after 10 years the devices will still transmit within the specified time difference between the starting and the stopping time.

In single-sensor operation, a constant value is specified for the ambient temperature and only the radiator temperature is measured. In dual-sensor operation, the actual temperature difference between the ambient temperature and the radiator temperature is determined. The measurement recording takes place by means of one (radiator) or two temperature sensors (radiator and room air temperature sensors).

With large radiators, it may be that two heat cost allocators have to be attached because of the uneven heat distribution. In these cases, the heat output of the radiator is assessed as the average value between the two heat cost allocators. This ensures that heating costs are not paid twice. The aim of this measure is to record the heat output correctly.

With uniform scales, each heat cost allocator is programmed with the same heat transfer coefficient values. When the bill is drawn up, the display values are multiplied by the radiator's individually determined rating factors. The rating factor depends on the radiator's heat output, the radiator type and type of installation, and is normally printed on the bill. The sum of the values determined in this way is reflected in the bill as the unit of consumption. With product scales, each heat cost allocator is already programmed with the heat transfer coefficient values which match the radiator. The display values on the heat cost allocator are identical to the values on the bill.

Heating cost distributors only operate if the temperature of the radiator is higher than the room temperature.

Electronic heat cost allocators measure the heat output of a radiator much more accurately than evaporative heat cost allocators. This is because the room temperature is also taken into account in the electronic heat measurement. Our heat cost allocator Q caloric is programmed to distinguish very precisely between ‘real’ radiator heat and other heat sources, such as solar radiation. Thanks to the very high temperature sensitivity, metering errors are greatly minimised with this technology.

With evaporative heat cost allocators, unwanted external influences such as humidity or solar radiation affect the measurement. This leads to inaccuracies of up to -/+ 15 per cent in the measurement.

Another advantage of electronic heat cost allocators is that, unlike evaporative heat cost allocators, they can measure precisely on the meter reading date and display different types of value. These include, among other things, the annual consumption value on any due date and the current consumption. In addition, the display can be compared directly with the annual bill.

All heat cost allocators used in Germany must be tested and approved in accordance with § 5 of the German Heat Cost Allocation Ordinance (HKVO). The technical basis for this is laid down in the European Standard EN 834 for electronic heat cost allocators.

European standard EN 834 (Point 6.3) stipulates that only those mounting points on the radiator where the average heat output is most effective over a wide temperature range should be selected. Depending on the radiator type, the mounting location, mounting height and type of mounting are therefore prescribed in detail.

As a rule, the installation of the heat cost allocators must be carried out at 75 percent of the radiator height for both evaporative and electronic heat cost allocators. Nevertheless, the optimal installation points for radiators that look similar can sometimes differ considerably. Therefore, only an expert can make a correct assessment.

This is how the installation of our heat cost allocator Q caloric 5.5 is carried out:

Heat cost allocators are devices that determine the relative share of a radiator in overall consumption. They are an inexpensive way to divide heating costs fairly among residents. They have proven themselves millions of times over – and have been doing so in Germany since the 1920s.

The heat cost allocators are mounted directly on the radiator, where they measure the temperature difference between the radiator surface and the room temperature. There are two types of measurement: either by electronic heat cost allocators or thermodynamically by heat cost allocators that work on the evaporation principle.

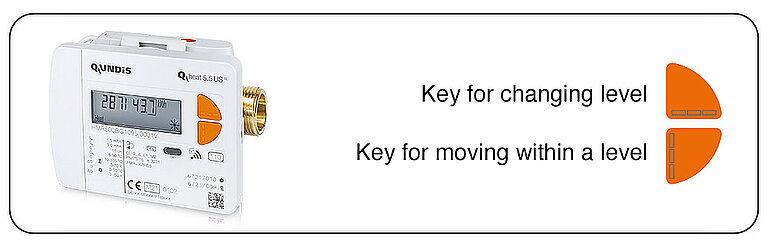

With any electronic heat meter you can display the current and annual consumption by using the following key combination: press the top button twice and the bottom button once to access the menu. Level L0 shows you the current consumption, level L1 the annual consumption. You can switch from level to level using the top button, and move within the level using the bottom button. To switch from a level back to the menu, press both buttons simultaneously.

With the generation of devices from 2016 onwards, reading has been simplified even further. After you press any button, the display shows the current consumption, the meter reading date and the metering date value in a loop. It is repeated ten times. A display test separates the display of the current value from the metering date value (annual consumption value).

Heat meters are used to measure the energy consumption of central heating systems or connections to district heating networks. They are installed directly in the pipe network of the heating or cooling circuit. In homes they are used, for example, in underfloor heating systems.

In accordance with § 9 (2) of the Heating Costs Ordinance, since 1 January 2014 heat meters have also been mandatory in Germany for hot water separation, i.e. separate energy measurement for hot water production.

In addition, heat meters are useful for measuring the energy of heat pumps and solar thermal systems in order to comply with funding guidelines.

With a dynamic range of 1:100, the metering accuracy of an ultrasonic heat meter is higher than that of conventional heat meters, in which the volume flow is measured using an impeller. In our model – the Q heat 5.5 US R – this is achieved by means of a patented process in which the transit time differences of acoustic signals are measured via contamination-resistant, high-quality mirrors in the single-pipe connector.

Nevertheless, classic impeller wheel heat meters such as our Q heat 5.5 R provide highly accurate readings (dynamic range 1:50). They are perfectly adequate for conventional applications, such as recording consumption in heating or hot water systems. Ultrasonic heat meters are often used where volume flows have to be determined very accurately – for example, in domestic connections or for hot water separation.

In addition, ultrasonic heat meters are subject to almost no restrictions with regard to the position in which they are installed. In contrast to classic impeller wheel heat meters, they can also be mounted overhead, for example.

We offer various types of electronic heat meters. All the data sheets for our devices can be found in the Download & information section. There you can read what appears on your heat meter display.

Heat meters, also known as heat volume meters, record the heat energy that is supplied via a heating circuit or removed from a cooling circuit. The device measures the volume flow of the medium (e.g. water or glycol mixtures) and the difference between the supply and return temperature. The relation of these values indicates the consumption in kilowatt hours (kWh), megawatt hours (MWh), megajoules (MJ) or gigajoules (GJ). Heat meters are subject to calibration. They must therefore be replaced or recalibrated every six years.

Our electronic heat meters Q heat 5.5 R and Q heat 5.5 US R are among the most modern devices on the market. Thanks to their wide range of features and very compact dimensions, they can be used for numerous applications (e.g. hot water separation, solar circuits).

In almost all federal states, there is now an obligation to bill for cold water in residential buildings. This is a good thing, because the installation of cold water meters leads to significant savings in water consumption and to a consumption-based allocation of costs among tenants. You can find out whether there is an obligation in your federal state in the relevant state building regulations.

QUNDIS supplies two types of domestic water meter: mechanical meters with a rolling counter and electronic meters with a digital display.

With mechanical water meters, the consumption level in m³ counts up continuously. Therefore, the reading must be carried out exactly on the due date (e.g. 31 December). If there is a radio add-on module on the meter, the metering pulses are transmitted directly to the metering service by radio on the due date. For subsequent checking, it is advisable to read the meter on the due date using the rolling counter.

Electronic water meters normally show the cumulative volume, a segment test, the meter reading date and the annual consumption value on the display in regular alternation.

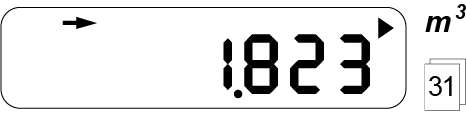

1. cumulative volume

The cumulative volume is displayed in cubic meters to three decimal places. The example shows 1823 litres.

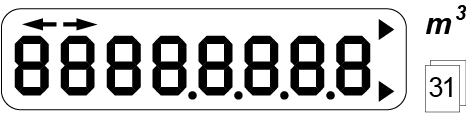

2. Segment test

This display is intended to ensure that all segments of the display are work properly.

3. Display of annual consumption value

Calibration law stipulates that hot and cold water meters must be calibrated every six years. The owner of the house or apartment is responsible for ensuring that the calibration requirement is met.

The year of calibration can be seen on the water meter via the adhesive label. For newer metering devices that are placed on the market in accordance with the provisions of the European Metering Instruments Directive (MID), a CE M mark replaces the national calibration mark. This is printed on the casing. The letter ‘M’ stands for metrology, while the number printed to the right of it within the black box (e.g. ‘21’) stands for the year of the conformity assessment. The above calibration validity periods also apply without restriction to these metering devices.

QUNDIS hot and cold water meters with a flow rate of Q3 = 2.5 m³/h (MID) are ideally suited for the consumption-based billing of water consumption in a single residential unit. If the property to be equipped has up to 30 residential units, the water consumption of the house connection can also be measured using our equipment – usually with the electronic Q water 5.5 surface water meter (Q3 = 4 m³/h, installation length 130 mm).

When making the selection, all the important factors of the local water supply should always be taken into account, including, for example, its stability. The decisive factors for the correct selection are almost always the maximum predicted flow rate in m³/h and the pressure loss.

Discrepancies between the meter reading of the house connection and the cumulative consumption values of the water meters in the apartments are part of everyday life. This is due, for example, to leaking sections of piping, unrecorded communal taps, very low flow rates or varying accuracy classes or installation positions of the water meters. The legally tolerated measurement limits for water meters are ± 5 per cent.

However, this does not disadvantage residents in any way, as these differences occur in all apartments. Apartment water meters are used only for consumption-based cost allocation. The consumption values of the main water meter are used to bill the actual building consumption on the basis of cost units.

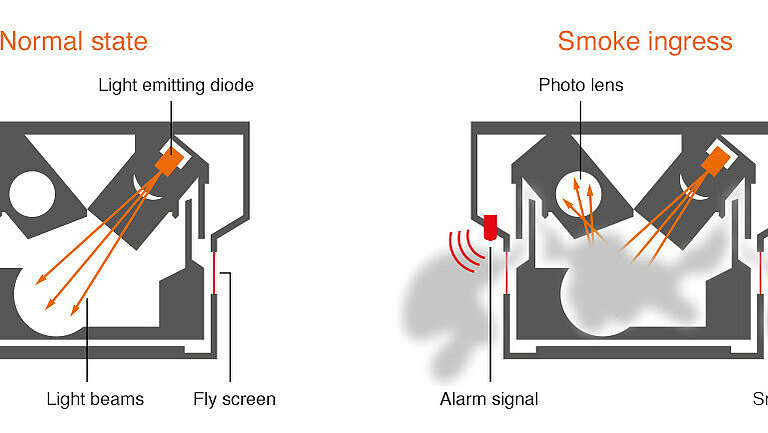

Our smoke alarms work on the scattered light principle. When smoke reaches a certain concentration, the light in the device is directed onto a photocell, triggering the audible alarm. The test button on the Ei650i smoke alarm can be used, for example, to check whether one or more alarms have been triggered within the last three months. In addition, the LED flashes to indicate the status. For optimal protection, you should install a smoke alarm in every room where a fire could potentially break out (except for kitchens and bathrooms).

The national application standard DIN 14676 regulates the planning, installation, operation and maintenance of smoke alarms. This standard applies to private homes and rooms with similar residential use. It is intended for the authorities responsible for fire protection, fire brigades, smoke alarm manufacturers, planners, homeowners and residents. Important to know: Only smoke alarms that fulfil the requirements of EN 14604 may be used in the EU.

Furthermore, the state building regulations (LBO) of the individual federal states regulate the obligation to equip existing and new buildings with smoke alarms.

Before smoke alarms became popular in the domestic sector, smoke detector systems were almost the only ones to exist in Germany (e.g. in hospitals, warehouses, hotels). The government created a corresponding standard early on, in which the detectors were referred to as smoke detectors. However, these detectors were not designed to warn people of dangerous smoke concentrations by beeping loudly, but to report a fire directly to the fire brigade – even if there were no people in the building.

With the increasing prevalence of smoke detectors in homes, it was found that the name was already taken. From then on, the acoustic warning devices were called “smoke alarms”. Even if the term smoke detector is used, in most cases it refers to a smoke alarm. Our portfolio includes only such smoke alarms.

Please note that the lifespan of a smoke alarm device is 10 years. The long service life is achieved by a permanently installed lithium battery and increases safety. This is because you no longer have to worry about regularly changing batteries. Furthermore, the device must have a CE marking. This proves that the smoke alarm device complies with the European device standard EN 14604 and has been tested and approved according to its strict criteria.

The coveted ‘Q’ label is only awarded to devices that meet the particularly strict standards. The ‘Q’ stands for the highest quality of smoke alarms. This seal of approval provides information on whether a smoke alarm is suitable for long-term use over a period of 10 years.

The application guideline DIN 14676 stipulates how a smoke alarm device is to be installed. The following key points provide an initial overview of some of the most important requirements:

Important: the QUNDIS smoke alarms with an integrated radio module do not replace a central fire alarm system. If, in the event of smoke or fire detection, an alarm is to be forwarded to the fire brigade, a central fire alarm system must be used in accordance with DIN 14675.

Smoke alarms are not suitable for bathrooms or closed kitchen areas. They should be at least 90 cm away from kitchen and bathroom doors, compressed air lines for air conditioning systems or heating systems, ceiling fans and house fans.

Likewise, smoke alarms should not be installed in very dusty areas (e.g. workshops). During renovation work that involves a lot of dust, you should cover the smoke inlet openings of the devices until the work is finished or remove the devices completely. Never paint over smoke alarms!

When the test button is pressed, the indicator light flashes at regular intervals to show that the smoke alarm is working. In the Ei650i, the LED brightness is automatically reduced from 10 p.m. to 6 a.m. In the Ei6500-OMS, there is no signalling during normal operation. Fault messages are suppressed during this time in the Ei650i and signalled continuously in the Ei6500-OMS; an alarm is still raised in an emergency.

When the Ei650i or Ei6500-OMS is screwed into the previously attached mounting base, the device is automatically activated. An audible signal confirms that it is ready for operation.

During the remote inspection, the smoke alarm device transmits the necessary status information about its operating state to the radio network in the building. This information allows the landlord to see very early on if a device is faulty. The device can be replaced directly, for example, during the annual visual inspection.

The following status messages regarding handling and operating status are transmitted by the radio-controlled smoke alarm Ei6500-OMS to the remote meter reading system:

High quality smoke alarms, such as those produced by QUNDIS, do not register cigarette smoke, because they recognise the difference between cigarette smoke and the very small but dangerous concentrations of smoke which may be present in buildings. Thanks to the inbuilt dirt compensation, this mechanism works reliably over the entire lifespan of the device.

Dirt compensation

Our smoke alarms permanently monitor the dirt in their measuring chamber. If dirt particles are detected in the measuring chamber, they adjust their alarm threshold so that the distance to the basic signal always remains the same. The smoke alarms from QUNDIS do not become more sensitive due to dirt, which means that the operating time is increased many times over. As a result, false alarms can be avoided to a large extent.

Dirt prediction

Our smoke alarms can determine the state of their measuring chamber through a process known as alarm threshold adjustment. At regular intervals, the device measures how much the measuring chamber is clogged with dirt particles – the higher the level of contamination, the further the alarm threshold is lowered. During the annual function test, the devices automatically generate a forecast as to whether they will continue to function properly for another 15 months if the level of contamination remains the same. If the forecast indicates that the contamination of the measuring chamber is so severe that the alarm threshold can no longer be adjusted, the function test will fail.

AMR stands for Automatic Meter Reading, a process for fully automatic remote meter reading via the Internet. The network nodes in the stairwell are the centrepiece of the system. They receive the consumption data from the metering devices every four hours. Since the reception range of a network node is limited by the nature of the building, in larger residential properties several network nodes form a meter-reading network. At least one of these nodes is in direct communication with the gateway. This device in turn connects to the Internet via mobile network to the metering service and transmits the meter readings. The consumption data is then immediately available for various services (billing, statistical analysis, etc.).

No, QUNDIS does not receive any personal data from tenants, such as names, addresses, etc. The data recording and transmission is carried out exclusively by the metering service provider. To protect your personal data, we have no insight into the circumstances of your residential property.

The consumption and meter data is initially only available to the metering service provider commissioned by your landlord or property manager to record the consumption data. They install and operate the meters and transmission devices.

After taking the meter reading, the metering service links the consumption and apartment data to create a consumption-based utility bill. The metering service then sends the billing documents to the landlord or property manager so that they can carry out the billing for the building.

Your landlord or property manager will be able to provide you with more detailed information on this.

Meter reading by radio usually involves transmitting the following consumption and meter data from the meter to the metering service:

The radio telegrams of the QUNDIS devices are based on the OMS specification, which is currently the most modern radio standard for the remote reading of intelligent meters in Europe.

Radio reading means that the heat cost allocators, water and heat meters automatically transmit the recorded consumption values of your apartment to the metering service by radio. It is no longer necessary for anyone to enter the apartment for the heating cost bill. This procedure is always used when the metering devices have a radio interface or have been retrofitted with radio add-on modules.

The radio reading is done either by mobile or stationary data collectors via network nodes in the stairwell. The procedure has several advantages: the data is always recorded on the due date. Also, if you move house, the meter reading service does not have to read the meter on site. This makes moving in or out a lot simpler.

From an electromagnetic point of view, our radio system is absolutely harmless. The transmission power of our radio meters is well below 10 milliwatts. Current radio telephones (4G) have an average power of 200 milliwatts. This means that the average radiation power of a mobile phone is up to 20 times higher than that of a QUNDIS radio system. The optimised transmission power and the minimal transmission duration of the metering devices ensure that they are well below the limit values of the Federal Emissions Control Ordinance.

Various password levels in our software prevent unauthorised persons from accessing the data. Due to the special structure of the data telegram, the data cannot be decrypted without processing with our software components (radio software, device drivers). Likewise, the lack of specific assignment of the devices (location-based data such as tenant name, apartment, etc.) means that no conclusions can be drawn about user behaviour. These technical features reliably prevent the data transmitted by our radio systems from being misused.

If your measuring device is damaged or defective please contact your metering service.

All QUNDIS devices carry out an internal check every four minutes. If the check indicates that there is a problem, an ‘Error’ message is displayed. You should report this to your metering service.

Your measuring service will check if your devices are installed correctly.

The reading and maintenance of your devices is implemented by the metering service which is responsible for you.

Consumption-based billing makes a considerable contribution to sustainable consumption of energy and water and accordingly to conserving the climate. Investigations indicate that the existence of metering devices on their own makes possible savings of between 20% and 30%. We only use our resources economically if consumption is measured. Blanket distribution, on the other hand, promotes waste. Consumption-based billing is mandatory in accordance with § 4 of the heat cost directive.

From an electromagnetic point of view our radio system is perfectly safe. The transmission output of our radio metering devices is well below 10 milliwatt. Current mobile phones (4G) have an average output of 200 milliwatt. As a result the average radiation level of mobile phones is up to 20 times higher than is the case with the QUNDIS radio systems. The optimised transmission performance and minimal transmission time of the metering devices ensure that the relevant levels are well below the limits imposed by federal emissions protection regulations

Various password stages in our software ensure that unauthorised persons cannot gain access to the data. Because of the special structure of the data telegram, the data cannot be decrypted without being processed by our software components (radio software, device drivers). The fact that the devices cannot be assigned (local data such as the name of the tenant, flat number etc.) means that no conclusions can be drawn about user behaviour. These technical features reliably prevent any manipulation of the transmitted data within our radio systems.

No, replacing the batteries is not possible. The device has to be replaced completely.

Because of calibration obligations warm water meters and heat meters have to be calibrated every five years and cold water meters every six years. The owner of the property is responsible for meeting calibration obligations.